Material testing machines

Adria Tools provides industrial machines produced by GALDABINI and BOWERS, for tensile testing, compression, straightening machines, hydraulic presses and hardness testing machines for Rockwell, Vickers, Brinell and Universal testing

Continue Reading

Hand measuring tools

Wide range of high precision measuring instruments, bore gauges from Bowers and hand measuring tools M&W including calipers, micrometers, hight gauges, protractors, indicators etc, traditional industrial measuring tools

Continue Reading

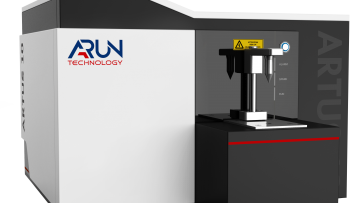

Spectrometers

ARUN Technology has been dedicated to the design, development, manufacture, sales and service of optical emission spectrometers since launching the world’s first portable CCD based metals analyser in the 1980’s.

Continue Reading

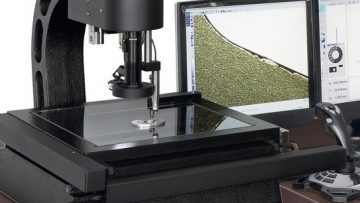

Optical measuring

Fast and easy non-contact measurement for both simple and complex samples, for testing values such are length, angle, diameter, radius or combination in single operation, shorter operating time, reduced costs and increased efficiency.

Continue ReadingRecent Videos

LOOKING FOR RELIABLE SOLUTION FOR YOUR COMPANY?

REQUEST A QUOTEWhat You Can Expect From Us

TEAM OF EXPERTS

Adria Tools engineers are always at your disposal, ready to answer on most demand requests and fully dedicated to each task.

ABOUT USCERTIFIED EQUIPMENT

All equipment produced according to international standards, supplied with our without certificates depending on customers request.

PRODUCTSPROMPT ANSWER

We can reach each customers facility same of next day after request, in order to enable customers processes working without delays.

CONTACT USTECHNICAL SUPPORT

Our team consists of mechanical engineers, ready to solve each technical issue related to our equipment in pre-sales and after-sales period.

CONTACT USFrom Error To Micron

Today most of the operators and engineers in factories all over our region are not familiar with new technologies related to measuring. Due to our continuously following of technical development and world industry progress we are looking forward to provide you consulting services.

Each production is followed and ends with quality control – it is process that should be always improved. We can be you external partner in quality assurance and support your engineers in finding best solution for your production.

Our team of engineers have decades of experience in solving measuring problems in almost all important factories in our automotive, defence, aerospace, medical, education, chemistry, mechanical industry.

Besides implementing of complex measuring systems, we can provide special measuring holders and accessories designed and manufactured according to specific request.

Engineering processes in some cases are supported by our supplier’s engineers.

We provide all of our equipment directly to your warehouse or laboratory. Each delivery is carefully followed by our employees, starting from loading up to delivering to your facility.

In order to deliver the shipment according to customer’s request, we have agreements with several logistics companies. We are able to provide your shipment status information at any time. All of our goods are delivered to Serbia with minimal transport costs, but at the same time we are able to provide best solution for each shipment – ether if it is lower cost or shorter delivery time, sometime both.

Sophisticated equipment requires experts for unpacking and installation. Therefore we are installing all of our machines and products that are not as simple as calipers are.

Our experienced engineers will carefully unpack each machine delivered from our company, check if all parts are included, place the machine on its place and connect all the parts in order to set the machine ready to use. Through that process, operators that will use machines will be able to get to know parts of the system.

Each machine is followed with user’s manual translated in Serbian language, for installation and use of the machine.

Each machine must be fully functional before its usage, but functionality is not possible without educated operator.

Adria Tools provides training of operators for each delivered machine. Training includes not only handing with the machine, but also software learning and samples preparation. Through training process, operator will be introduced about usage and purpose of the machine and all basic knowledge about testing itself.

Most of our machines are remotely controlled (with your approval) from producer’s and our office.

All equipment supplied by our company is fully supported within warranty and after warranty period!

Service of the equipment is done by our engineers and directly producer’s service engineers. Most of the services can be done at your site, at short period of time.

We are aware that production requires fully functional machines every working day. Therefore we are taking care of each delivered machine and remind you when there is need for prevent maintenance. We can quickly deliver spare parts and do replacement when it is needed.

Your fully functional machine is our benefit.