Quality products, innovative technology, expert support and world-class service

From our diverse areas of specialization, GALDABINI and BOWERS carry out research into technologies and applications that provide innovative solutions, according to customer’s specific needs. Sectors and industries in which our products are used are:

- Aerospace

- Automotive

- Defence

- Energy

- Medical

- Electromechanical

- Cookware/ Houseware

- General Mechanics

- Labs (Quality Testing)

- Educational

About Galdabini testing machines

Galdabini is a “worldwide family company”, well aware of their responsibility towards customers, partners and employees. It has been over a century since Galdabini manufactured their first machine. Nowadays factory goes further than just manufacturing machines, Galdabini has innovate in testing, straightening and metalforming.

Galdabini strong values and philosophy put customers first, working with dedication and commitment to come up with the best technology and set new standards in the machine industry.

Founded in 1890, a private company owned by Galdabini family

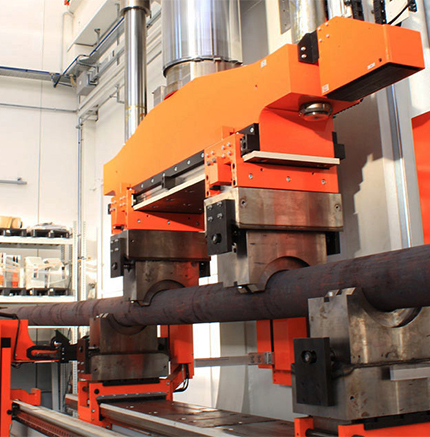

GALDABINI manufactures and services material testing machines, straightening machines and hydraulic presses. The company is composed by two corporate headquarters located in Italy and Switzerland, providing you high technologies, quality and a long lasting know how. Specialized in material testing machines to analyze mechanical properties of various materials and components – suitable to carry out material tests as tensile, flexure, compression, bending and impact. Leader in straightening machines for shafts, profiles, rings, tubes and bars. A wide range of straightening machines and solutions is suitable for application in automotive and non-automotive fields. High efficiency and performances in hydraulic presses and turn-key production lines to satisfy a large range of requirements for steel and aluminium forming. A qualified staff supports you on-site during installation, training and calibration on a world-wide scale. GALDABINI is an official European Calibration Centre for load, deformation, resilience hardness and other typical units.

About Bowers hardness testing machines

BOWERS supply a quality range of hardness testing instruments, systems, software and accessories. The products are used to evaluate the hardness properties of all types of steel, metals, alloys and plastics. With a wide range -, fit to any budget -, offering both traditional and state-of-the-art testing instruments, our products are a market leader in hardness testing solutions.

We are committed to solve your testing requirements and not just selling products:

- Solution driven

- High quality standard

- Traditional and state-of-the art technology

- Solutions and technology that fit your budget

- Global local service capabilities

- Superior guarantee system

We have large confidence in our products! Therefore we offer a (limited) guarantee of 2 years or longer on all our products. All instruments are supplied with a quality and guarantee certificate and a service passport.

About hardness

Hardness is the property of a material enabling it to resist plastic deformation, usually by penetration of another object. The term “hardness” may also refer to stiffness, temper or resistance to bending, scratching, abrasion or cutting. In materials science there are three principal operational definitions of hardness:

- Scratch hardness:

Resistance to fracture or plastic (permanent) deformation due to friction from a sharp object.

- Indentation hardness:

Resistance to plastic (permanent) deformation due to a constant load from a sharp object.

- Rebound hardness:

Height or speed of the bounce of an object dropped on the material, related to elasticity.

Measuring hardness

Hardness is not an intrinsic material property. There are no precise definitions in terms of fundamental units of mass, length and time. A hardness property value is the result of a defined measurement procedure.

The usual method to obtain a hardness value is to measure the depth or area of an indentation left by an indenter of a specific shape, with a specific force applied for a specific time. There are several principal standard test methods to express the relationship between hardness and the size of the impression or the rebound velocity on specific materials.

Vickers, Rockwell, Brinell and Leeb are the most common scales.

For practical and calibration reasons, each of these methods is divided into a range of scales, defined by a combination of applied load and indenter geometry or in case of the rebound method, by the weight of the impact body.